The Best Strategy To Use For Screen Printing Custom T-shirts Abilene

Screen Printing Custom T-shirts Abilene Fundamentals Explained

Table of ContentsScreen Printing Custom T-shirts Abilene Things To Know Before You BuyAll about Screen Printing Custom T-shirts AbileneThe Definitive Guide to Screen Printing Custom T-shirts AbileneWhat Does Screen Printing Custom T-shirts Abilene Mean?What Does Screen Printing Custom T-shirts Abilene Mean?The Ultimate Guide To Screen Printing Custom T-shirts Abilene

No mixing required, cures exceptionally rapidly, expensive, suitable for detailed job. Combination of Diazo and SBQ, requires mixing, total cure time is less than Diazo, cost is reduced than SBQ. The transparent acetate film is put on the emulsion-coated mesh screen carefully under an intense light which causes the emulsion to harden and develop.Exposing the screen for a specific time will certainly solidify the uncovered areas of the screen, and the remaining unhardened solution, if any kind of, will be rinsed away to leave a clear imprint on the display. The screen is after that dried out, and if there are any type of touch-ups required, it will be done by the printer to make the imprint as near to the original layout as possible.

The material to be printed is positioned flat on the printing board, and the screen on top of the material in the wanted setting, ready to be published. In this action, the printed style will certainly revive. The screen is decreased down to the printing board. The wanted colour ink is included in the top of the screen.

The ink presses via the open locations of the pattern and transfers on the underlying silk, as a result publishing the style on the product. The stencil will certainly have served its objective as soon as all the items are printed. A special washing liquid is used to eliminate the solution to reuse the mesh for developing brand-new stencils.

Get This Report about Screen Printing Custom T-shirts Abilene

This is done so that the layout does not diminish. There are 6 different kinds of display printing procedures. Considering that various methods will supply various results, it is necessary to comprehend the various types. One of the most usual screen printing method is spot colour screen printing. Place colour screen printing uses the ink's stock colour by printing it via the pattern of the mesh.

It is much less complex to use as contrasted to other display printing methods. It can be an outstanding option for printing on tee shirts, jackets, and hoodies.

In addition, it is an affordable method considering that just one colour of ink is used. Grayscale printing is an outstanding method of printing full-colour images as one colour grayscales or halftones.

How Screen Printing Custom T-shirts Abilene can Save You Time, Stress, and Money.

Duotone printing makes use of the combination of two halftones for publishing the same photo with 2 colours. A black halftone is printed with black ink, and after that a 2nd halftone is published with colour ink. This technique is similar to sepia-toned print in photography. It offers an advanced and artistic effect.

The substitute printing procedure combines the four-colour printing procedure with place colour printing. Because this method is helpful for both lighter and darker shades, it is flexible and popular with individuals looking to generate photorealistic print detail.

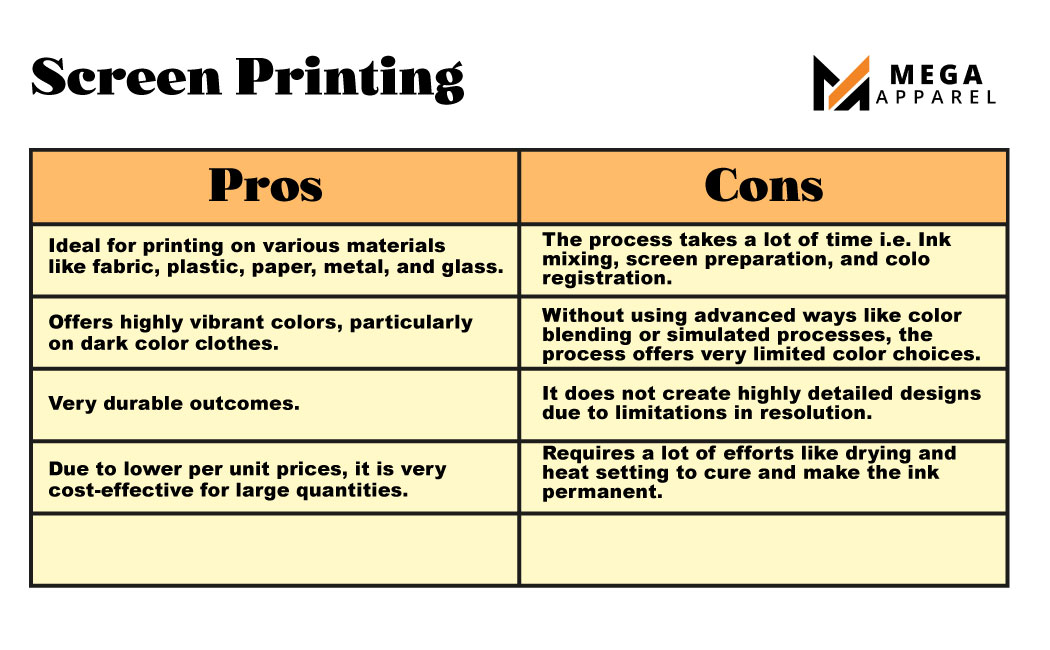

Several of these advantages include: One of the main advantages of display printing is its adaptability. It can be used on any type of kind of material, plastic, wood, glass or perhaps metal. And also, numerous colours can be used. There is practically endless layout freedom when making use of screen printing. Contrasted to other printing approaches, display printing can use a heavy ink coverage, resulting in a resilient design.

The smart Trick of Screen Printing Custom T-shirts Abilene That Nobody is Talking About

Screen printing is among the most reliable and rapid printing methods as soon as a screen has been produced. It is an exceptional alternative if the very same design is to be published over and over once more (Screen Printing Custom T-Shirts Abilene). The screen printing procedure is fairly straightforward, whether it is automated or done by hand. In addition, the needed tools are likewise not tough or expensive to replace.

Personalized screen printing is a process that uses a mesh screen to press ink in a fixed layout onto the textile of your option. Display printing is prominent for personalized tee shirts, sweatshirts, jackets, and a lot more. Custom-made screen published tee shirts or various other screen-printed garments are the perfect means for services to increase their brand existence.

5 Easy Facts About Screen Printing Custom T-shirts Abilene Explained

The ink's long life makes certain that prints endure duplicated washing and wear, making it ideal for textiles like t-shirts, hoodies, and shopping bag. This strategy deals with a variety of surface areas, including textiles, plastics, glass, wood, and steels. Its adaptability permits organizations and designers to apply designs to items like garments, advertising products, signage, and packaging.

Modern more info automated screen printing press streamline the procedure, enabling greater production rates while preserving consistent high quality. Automation decreases mistakes, ensuring every print equals and as much as specialist standards. Developments like computer-to-screen (CTS) and direct-to-screen (DTS) technologies are changing the screen printing process. These approaches eliminate the demand for traditional movie positives by digitally moving screen printing layouts directly onto the display.

Our Screen Printing Custom T-shirts Abilene PDFs

While rooted in practice, screen printing has actually accepted technical improvements to meet modern-day needs. Its combination of workmanship and innovation guarantees it stays a leading option for creative and industrial printing tasks. Screen printing proceeds to be a dependable and functional printing approach, offering vivid shades and long lasting styles that stand apart on a selection of materials.

Below are some of them. Display printing can create a various visual result when contrasted to digital printing. Display printing ink is normally used much more thickly, resulting in longer-lasting, brighter and a lot more vibrant colours, even on darker histories. For garment style that calls for a high degree of vibrancy when publishing on dark grounds, screen printing is still the finest alternative.

Hence higher volumes can be mass produced using screen printing a lot more rapidly and more cost efficiently for larger orders. Display printing fits a large array of materials, including plastic, fabric, inflexible plastic, foam board, steel, glass and several others.